drawbacks of brinell hardness test|brinell hardness test example : Chinese The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to . Zeus Night Club – A melhor casa de swing e boate liberal de Brasilia. A melhor boate Liberal de Brasilia. Acessar programação semanal. Grupo Vip da Zeus Night Club. .

{plog:ftitle_list}

WEBCasada peituda foi para o acampamento com o maridão, os dois saíram fazer trilha e acabaram fazendo um sexo muito safado no mato. No meio da trilha a gostosa peituda .

Disadvantages of Brinell Hardness Test. Not suitable for hard materials – The Brinell test can damage hard materials because the indenter may not be able to make a clear mark, leading to inaccurate measurements.

The Brinell Hardness Test method is used to evaluate the hardness of the object, especially for non-ferrous metals, cast irons, and steel products at the higher strength ranges .

In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is .

There are two disadvantages of Rockwell testing when considered against Brinell: The diamond indenters are very expensive and the test surface (and its underside) must be extremely clean. Note for non-engineers: . The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to .Advantages of the Brinell Hardness Tester. 1. Wide Applicability. 2. Large Indentation Size. 3. Cost-Effectiveness. 4. Material Homogeneity Evaluation. 5. Accuracy and Reproducibility. 6. High-Load Application. 7. Simple Test . 1. 0. Bookmark (0) Hardness Testing of Metals: Rockwell, Brinell, Vickers, Knoop, and Leeb Tests. This article provides an overview of common hardness testing .

The Brinell method has the following disadvantages: The surface quality of the specimen must be good, because the indent is measured optically. This means that the test location must be .Hard materials resist deformation, indentation or scratches making them harder wearing, longer lasting and often easier to clean and maintain. What are the disadvantages of hard materials? Hardness and toughness are normally .

Types of Brinell Hardness Test. The Brinell hardness test is categorized into two types: Standard Brinell hardness test: In this test, a load of 500 to 3000 kg is applied to the surface of the material for 10 to 30 seconds, depending on the . Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small .Related Article: What are the Advantages and Disadvantages of the Brinell Method? . Brinell hardness test is slower to perform with the estimated time of 30 to 60 seconds, while Rockwell hardness is fast enough to show results in 10-15 seconds.

Applications for Brinell Methods Brinell testing is suitable for measuring the hardness of rela-tively soft materials, including low-carbon steels, aluminum, lead, copper, and some plastics. The use of a large indenter and high load helps to minimize the effect of surface irregu-larities and yields more accurate hardness values. Soft Materials .The Vickers Hardness test has some disadvantages also which are as follows: The good preparation (grinding and polishing) of the surface of the sample is important as quality matters, otherwise, it is hard to get a precise estimation of the object as intended is evaluated optically. . The speed of the method is not very efficient relative to .The Brinell hardness test (HBW) serves as a crucial scale for quantifying material hardness, defined in ASTM E10 and BS EN ISO 6506-1 standards. This test involves pressing a Brinell indenter against a test specimen under a specified load and time duration. Typically, a hardened Tungsten steel ball, with varying force ranges based on material .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information about their hardness, toughness, and suitability for specific applications by subjecting materials to controlled indentation.

2002 toyota camry compression test

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

As Meyer hardness is measured using the Brinell hardness tester and the Brinell indenter, so the advantages and disadvantages associated with the Brinell hardness testing, mentioned in Sect. 3.6, will also be applicable to the Meyer hardness testing.

Duration of Brinell and Rockwell Hardness; The Brinell test is very slow (30 – 60sec). . Disadvantages of Brinell and Rockwell Hardness; Disadvantages of Brinell’s method are that hardness of ≥ 650 HB cannot be measured; the hardness is dependent on the load and according to X (degree of load) so it is necessary to choose the .

2002 ttr 125 compression test

The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left. The method proved reliable and in 1900 the . Advantages and disadvantages. The advantage of Rockwell hardness testing is the relatively short testing time and good automation capability, as the measured values are determined directly from the .

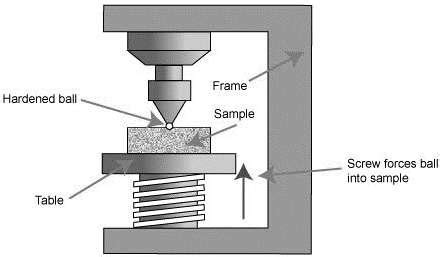

History Behind the Brinell Test. Let’s take a quick glance at the history behind the Brinell test. In 1900, Dr. J.A. Brinell invented this test. As an honor to him, the test named as a Brinell test. It is the oldest hardness test of all time. .What are the disadvantages of hard materials? Hardness and toughness are normally inversely proportional to each other e.g. glass is hard, but it’s low toughness makes it very fragile. Plastics are often tough, but not as resistant . The Brinell Hardness Test is a straightforward process that is often applied to materials with rough structures, like cast irons or forged metal samples. During the test, a 5mm or 10mm round carbide ball is pressed into the material using a very high test load, usually between 750kg and 3000kg. This action creates an indentation that is . 1) Brinell Hardness Test 2)Vickers Hardness Test 3)Rockwell Hardness Test 4) Scratch hardness test What are the advantages and disadvantages of brinell hardness test?

brinell hardness tester diagram

Brinell hardness test uses a steel or tungsten indenter of a specified size and a specified load to make an indent on the test sample. IV. Advantages and Disadvantages of Brinell Hardness. Advantages: The Brinell method does not require the test sample to be prepared for inspection. This method can be used to test materials with irregular surfaces.The Macro Brinell hardness test Macro Brinell hardness test measurement is calculated by the formula in which the applied test force (kilograms) is divided by the surface area of the developed indentation (square millimeters). The final value is called a pressure measurement, but it has no unit. The Macro Vickers hardness test

Brinell Hardness Tester is a rapid and accurate method to determine hardness value with ASTM E-10 compliance. Applying loads of up to 3.000 kgf, the Brinell test is ideal for castings and forgings.Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter . When the Brinell hardness test cannot be used, such as when the material’s HB value is greater than 450 or the sample size is too small, the Rockwell hardness test is used instead. This test involves pressing either a diamond cone with a top angle of 120° or a steel ball with a diameter of 1.59 mm or 3.18 mm into the surface of the tested .The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test force >= 49.03 N), more precisely with a test force of 29.42 to 1471 N. It is a differential-depth method.

The SUNNYSONG Portable Brinell Hardness Tester KH180 is a versatile and reliable tool designed to meet your hardness testing needs. With its portable design, high precision measurements, and batch testing convenience, this tester is an excellent investment for professionals and enthusiasts alike.A the Brinell test, though more complex than the rebound test, is still simple. Its results correlate well with tensile properties. Disadvantages. The Brinell test is not entirely reliable, the hardness indicated often being less then the of the material under test when working with hard materials.

brinell hardness test theory

2002 ttr 125l compression test

Resultado da Vind penge gratis på grund af den skarpe konkurrence. Det er ingen hemmelighed, at de online casinoer naturligvis driver en forretning. Det betyder, at de på en eller anden måde skal danne et økonomisk overskud på baggrund af deres kunder. Dog kan man heller ikke komme udenom, at .

drawbacks of brinell hardness test|brinell hardness test example